Contribution by Vivek Pandey – Supply Chain Consultant at Bristlecone

Inventory Management and therefore Safety Stock Management is one of the major challenges for most of the companies in today’s world of fluctuating demand. High Safety Stock leads to blocking of working capital and increases the operational cost. On the other hand, low levels might lead to loss of sale and customer dissatisfaction. The dilemma is whether to maintain safety stock and if yes, at what levels so as to avoid both stock-outs and excess inventory, the latter helping in reducing inventory carrying cost.

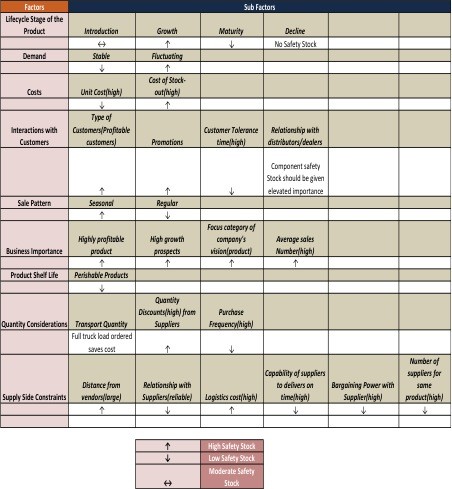

The quantitative and qualitative factors affecting Safety Stock and levels to maintain are shown in the table below:

Also for products which become obsolete in a shorter span of time, low levels of safety stock should be maintained. If the product has usability in making another product then stocks can be kept high. Safety Stock also depends upon the replenishment model: if it’s a vendor managed inventory, safety stock requirement would be low, while for order-based inventory requirement, it would be high.

Most systems used by companies pick up values of lead time, error in forecast and service level and use statistical formulas to come up with the optimal safety stock level. In today’s business scenario, it’s important to take other factors also into consideration as mentioned in the above table. It’s also important to revisit the formulation at regular intervals and make necessary adjustments.

Theory of Constraints (TOC) proposes a Dynamic Buffer Management (DBM) approach to complement the Replenishment System. It offers a methodology to monitor and adjust the buffer stock level. DBM is feasible and effective but is insufficiently rigorous. A timely adjustment to the buffer stock level will result in a lower average inventory level leading to inventory savings, and better service level to achieve higher customer satisfaction.

The TOC proposes the following solutions accordingly:

[list][item icon=”9733″ ]The inventory should be placed with the source of the supply chain (namely the plant). That is, products should not be delivered to the downstream companies as soon as they are finished; and distribution warehouses should not deliver products to the downstream companies as soon as products from upstream companies arrive;[/item][/list]

[list][item icon=”9733″ ]Each sale point only needs to store enough inventory needed for such a replenishment period;[/item][/list]

[list][item icon=”9733″ ]Each sale point should make up the replenishment in accordance with its sales, by replenishing how much it has sold;[/item][/list]

[list][item icon=”9733″ ]Sudden abnormal conditions should be monitored via the Buffer Management (BM) mechanism in order to prepare for any contingency. In case of a sudden increase in the sales resulting in low inventories, the BM can detect it right away and send out a signal for replenishment need.[/item][/list]

But the question is whether it considers the qualitative factors mentioned above and if yes how does it quantify the same. And if it doesn’t, there should be manual discretion.