CLICK HERE TO VIEW ORIGINAL WEB PAGE AT SUPPLY CHAIN 247

All too often, supply chain sustainability is reduced to a formulaic mold rather than the adaptable process it should be. By Sumit Kumar | SupplyChain247

Recent history has presented many examples of well-known companies – Apple, Walmart, Target and Tesco, to name a handful – facing the ire of customers, investors and governments due to flaws in their supply chains.

As a result, it is increasingly clear that unsustainable supply chains can have negative reputational, as well as financial, implications.

That realization is now elevating the sustainability of supply chains for organizations worldwide.

Part of the credit for this increased awareness also goes to organizations such as the Carbon Disclosure Projectand Global Reporting Initiatives for sharpening the focus around these topics.

Unfortunately, however, the approach to achieving sustainable supply chains has become a stereotype, as most organizations end up only meeting baseline compliance.

Purchasers go by clichéd “sustainable procurement guidelines” that list expectations from suppliers on common sustainability parameters and act as a screener at the time of on-boarding a supplier. But this approach defeats the purpose, especially for critical suppliers, because of its inherent limitations:

1. A straitjacket approach for all suppliers results in weak guidelines, which mostly seeks basic compliance to environmental, labor and human rights laws.

2. Once that weak guideline is met, there is little incentive for the suppliers to improve their performance.

These shortcomings then create a situation where neither the buying organization nor its suppliers are focused on improving the sustainability performance of suppliers beyond basic certifications.

Digging Deeper

In order to derive maximum value out of a sustainable supply chain and avoid supply chain disruptions, responsible organizations need to take ownership of their supply chain.

Here is an alternative approach CPOs can adopt to ensure sustainable performance of critical suppliers:

1. Think comprehensively with supplier assessments

Assess your critical suppliers by doing a comprehensive analysis of their performance on Environmental, Social, and Governance parameters. The assessment should be customized for each supplier, based on its industry and geography of operation.

Specific points that should be covered include: an evaluation of strategy, policy and other initiatives to tackle sustainability issues; an analysis of data reported on key sustainability performance indicators; a check for compliance with industry- and region-specific norms; and benchmarks for performance alongside industry peers.

2. Engage suppliers to discuss gaps

After dissecting a supplier’s sustainability performance, a buyer and a vendor should formulate a concrete plan to mitigate any potential risks to the supplier relationship.

Educating and collaborating with the supplier can help improve sustainability performance and reporting.

3. Keep tabs on progress

Monitor the development of a supplier, its given industry and geography on an ongoing basis.

It is also important to conduct periodic assessments of suppliers, with frequency dependent on how critical the relationship is to operations and how much risk exposure can be traced to a vendor’s sustainability performance.

4. Spread the wealth

Share the best sustainability practices adopted by leading suppliers with other suppliers, so that it becomes a win-win situation for everyone.

The goal is that ultimately, this effort will translate into goodwill and a stronger relationship with a company’s supplier base.

Cashing in on a sustainable supply chain

Having such a framework in place will give companies a better and deeper visibility into how critical suppliers operate both short- and long-term.

That means spotting both spot early warning signals for sustainability-related risks, and then the chance to proactively take steps to mitigate those risks.

At the same time, companies can uncover opportunities to work with suppliers to improve their own overall sustainability performance. Such opportunities can come through initiatives to reduce the environmental footprint of a supplier, leveraging supplier innovation to develop more sustainable products or other benefits.

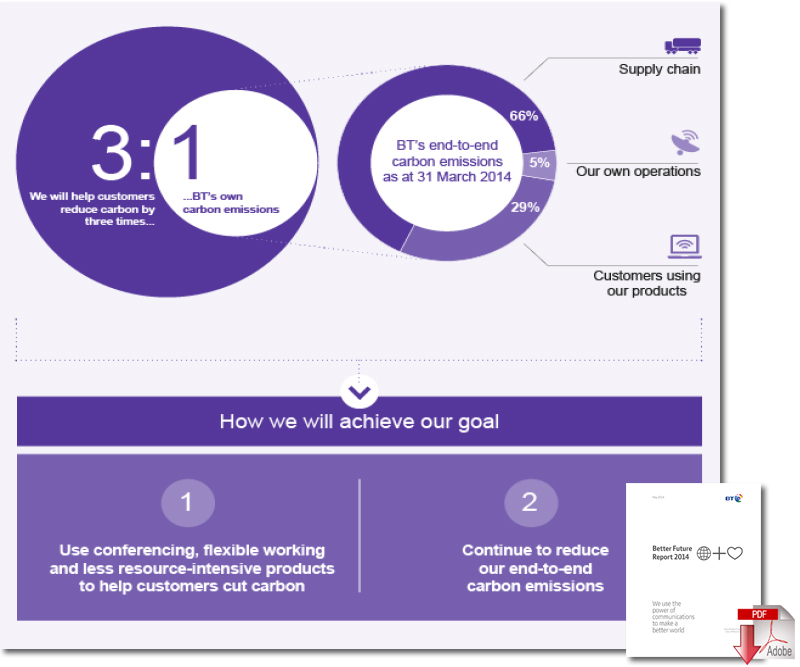

A very good example to illustrate the benefits of such a system is British Telecom, which adopted a similar approach to create Better Future Supplier Forum (BFSF) in 2012.

The company invites its select suppliers to this forum, where they are assessed and rated. It then engages its suppliers and helps them improve their sustainability practices.

In the first year of BFSF, one major supplier achieved 23,000 tons of carbon savings from changes implemented in manufacturing, packaging and logistics, which in turn reduced BT’s carbon footprint.

The process also educated suppliers on innovative designs that are not only more sustainable, but also more cost-effective. The platform also facilitates ongoing assessment and rating of suppliers’ sustainability performance, which helps determine awards for best performing suppliers and bolsters relationships.

If organizations start proactively managing the sustainability of their supply chains, they stand to benefit in the multiple ways: compliance with regulations on responsible and sustainable procurement; avoiding supply chain disruptions due to environmental, social, ethical and governance risks; a jumping off point for using suppliers to improve overall sustainability; and stronger bonds with business partners.

In the end, I believe more organizations should think beyond the sustainable procurement guidelines approach to maximize the benefits of their supply chain and strengthen the march towards sustainability.