By Lora Cecere, January 27, 2014, Forbes.com

It was supposed to be like a set of Legos. You had one. I had one. They had one. Each would be put it together in locked fashion. It has not worked out that way.

I love Legos. Each has a defined base and a set of connectors. They have standard sizes. You can easily assemble them into shapes and forms. Many business leaders have a similar concept about the building of the extended supply chain. It is not that simple.

Trading partners and value chains working together is a great concept. It is supposed to be that way. We have been at it for over two decades. Most leaders have at least one strategy document that proclaims this to be the goal. Leaders want to connect and manage the supply chain from the customer’s customer to the supplier’s supplier. However, we are not making progress. It is about more than waving hands or drawing it on a flip chart. Let me use some recent research to help readers face the HARD and COLD facts.

Definitions

Let’s start with some definitions. There is a progression of thought with each of the levels of maturity:

- Supply Chain. The processes within a company that connect the decisions for make (manufacturing), source (procurement), and deliver (distribution and logistics).

- Supply Network: When the supply chain is extended to a network of trading partners, it is termed a supply network.

- Value Chain: When the emphasis of this extended supply chain shifts from cost to value, it is called a value chain.

- Value Network: When it becomes more strategic to the company, focused outside-in to drive value-based outcomes, it is termed a value network. Value-based outcomes vary by industry. For healthcare today, it is health and wellness. For automotive it is safe and, low-carbon transportation. While for consumer products, it is winning at the moments of truth of product availability at time of purchase and delight at consumption.

Why Supply Chain Visibility is Important

The supply chain today is not the supply chain of yesteryear. There is more outsourcing. The product lines are more complex. Demand volatility is increasing. The nodes of the supply chain are more fragile. As we have grown more global and inter-connected, the impacts of failure are more pervasive. (A hiccup in one part of the world is quickly felt in another.)

This week, I am finishing a research study of eighty manufacturers. In the study, 32% of manufacturing and 42% of logistics is outsourced. This is a stark contrast to the studies that I have done over the years. At the dawn of the last decade outsourcing was about 50% of these numbers.

Customers want smaller shipments more frequently with a lower carbon footprint. A singular company cannot meet this need alone. To accomplish this goal takes a network.

Manufacturing outsourcing is necessary to achieve tax efficiency benefits and to enter new markets with new products. It is no longer just a game of labor arbitrage. A global manufacturer is a matrix organization of source, make and deliver operations. It is no longer a singular chain.

Insights on Supply Chain Visibility

Companies know that it is more complicated. But, they are not building the infrastructure to power value in networks. Let’s look at the facts of the study.

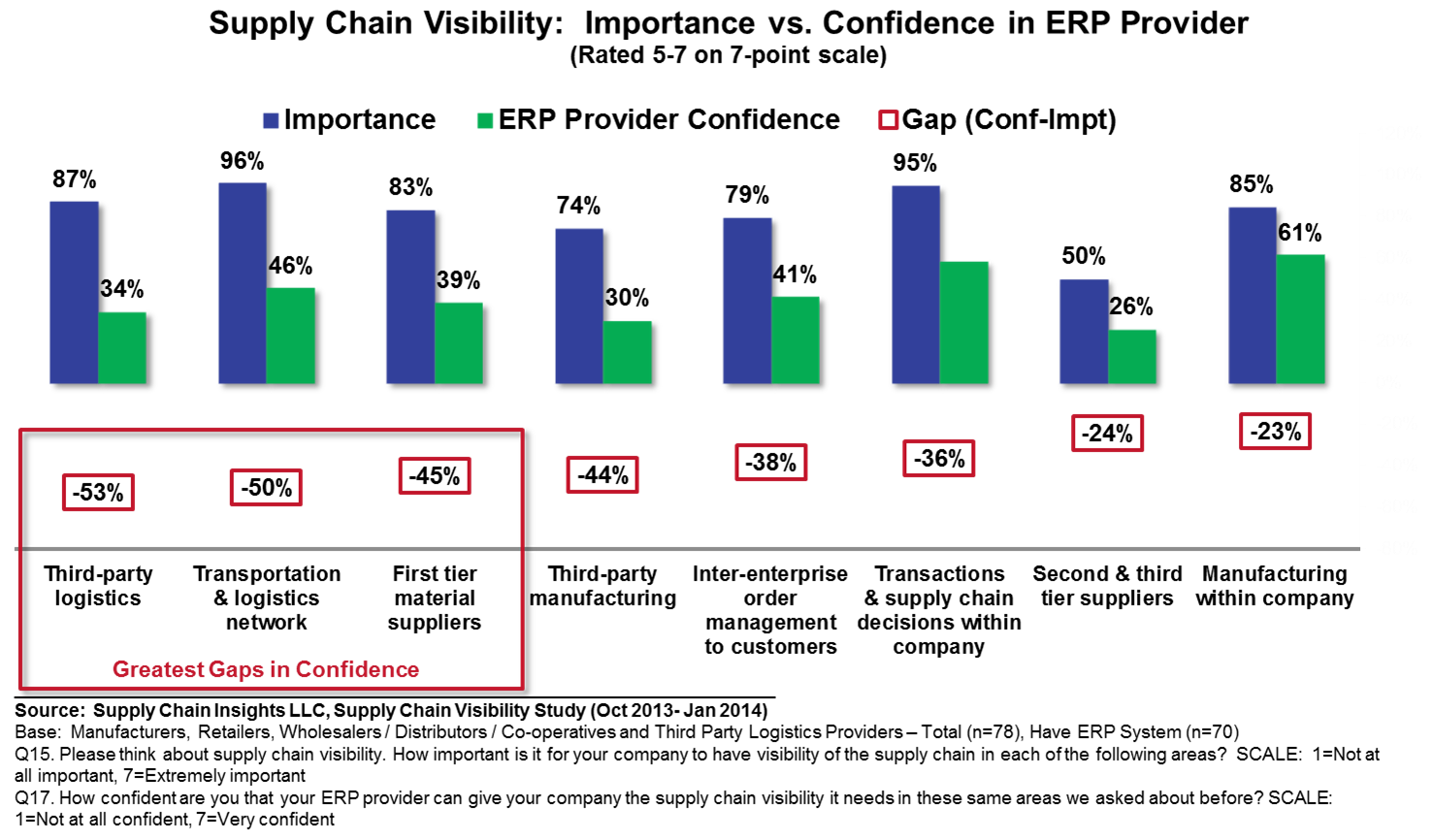

- Not as Easy as Lego Blocks. The primary investments of today’s corporation are in Enterprise Resource Planning (ERP from major software providers like INFOR, SAP and Oracle ORCL -1.34%.) The average company has not one, but seven instances. (Imagine seven Lego blocks….) And, while the company would like to use these investments to connect to trading partners, the study substantiates that the only value that is being derived from these investments is visibility of internal manufacturing. As shown in figure 1, the gaps in logistics and supplier visibility are large.

While the importance has grown, the gaps are not being addressed. Yet, most companies are pouring money into ERP architectures believing that it can be as easy as connecting your ERP to my ERP to their ERP. It is flawed logic. It is not as easy as Lego building blocks. This realization is slow. Today, only one out of four companies are confident that the ERP logic is equal to the task of delivering supply chain visibility to third-party logistics providers, contract manufacturers and first and second tier suppliers.

- IT an Enabler? Cloud and new forms of analytics offer new opportunities. It is more important to the business. Risk is higher. The line-of-business leader (head of manufacturing or leader of supply chain is not happy with the performance of the Information Technology (IT) departments. They feel stuck. One of the issues is that the investment in traditional enterprise applications like ERP are now a sink hole. Companies are pouring more and more money into these enterprise systems; and as a result, they do not have the resources to automate the extended network. As a result, in this study, only two in five supply chain leaders reported that they are satisfied with the how well their IT departments meet their needs.

- What to do? The first step is to realize that it is not as simple as a connecting Lego blocks. Start with a design session. Get clear on the basic definitions of planning. (Based on my experience, only one in ten companies are clear on the planning definitions.) After getting clear, focus outside in with a clear definition on synchronization and harmonization of data (Note: it is more complicated than integration). Look at new forms of inputs and evaluate new forms of business networks. We cannot wait for standards. The size of the prize is too big. Luckily new many-to-many architectures combined with new forms of analytics allow flexibility in data mapping and inter-enterprise systems of record. The key is to stabilize ERP and make it reliable, and then start the building of value networks.

Good luck on your journey. I hope that you can avoid this trap.